4,800 miles from Campus, the Work Goes On

Despite everything, the work of the Babson community goes on, in places near and far from campus.

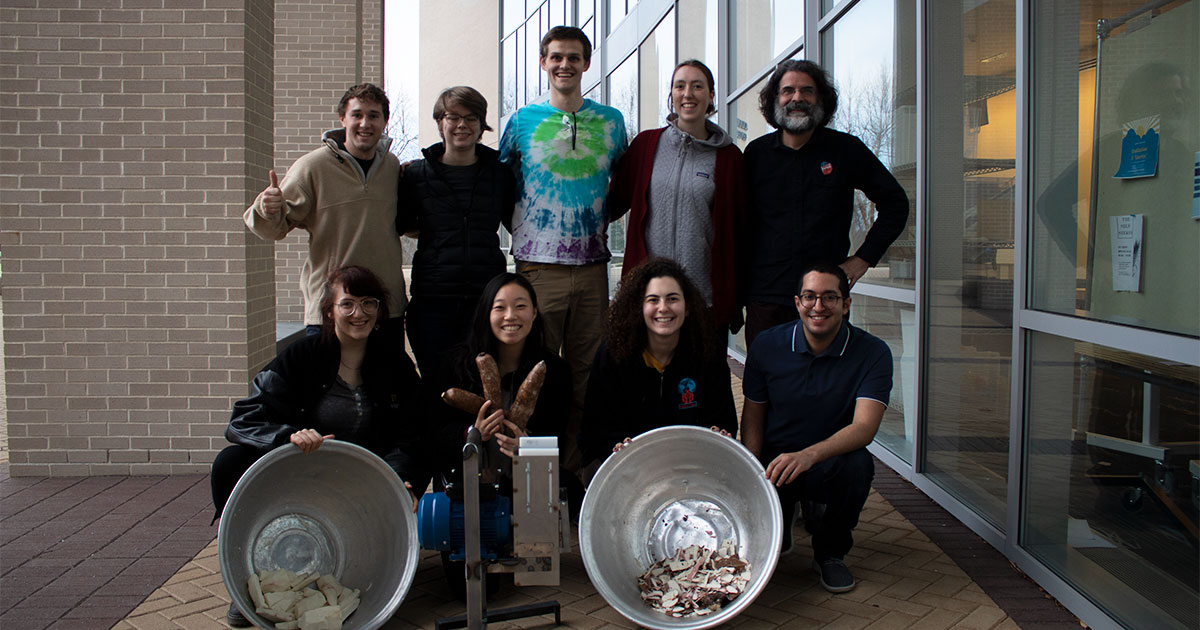

In West Africa, some 4,800 miles from Babson Park, a small nonprofit is receiving critical long-distance assistance from students. Based in Ghana, that nonprofit, QueenTech Initiative, provides food-processing machines that can allow woman entrepreneurs to launch and grow their own food ventures.

“We believe that QueenTech can make a massive impact in Ghana,” says Khalid Alayoub ’21, who’s working with the nonprofit as part of a course, Affordable Design and Entrepreneurship, that helps students to address social challenges.

The pandemic may have disrupted life on campus, but the students in the course, who hail not only from Babson but also from neighboring Olin and Wellesley colleges, have soldiered on. They know that their help is essential, in particular with much-needed fundraising.

“The work continues,” says Alayoub. “We’re trying to be as productive as we can.”

Supporting Women

Alayoub has long had an interest in agriculture. When he was a child, he spent weekends on his grandfather’s farm in Kuwait. He would walk through the vegetables, and he enjoyed seeing the animals. “I liked the openness and how calm and quiet it was,” he says. Alayoub also was aware how hard working the land can be. “Farming is burdensome,” he says.

Alayoub was intrigued when he heard about Affordable Design and Entrepreneurship. He relished the chance to work with students in different disciplines from other schools, and he liked that QueenTech supported women in agriculture. As in many parts of the world, women face severe inequality in Ghana. “There is a big gap in the resources available to women compared to men,” says Alayoub. “The opportunity to close that gap drew me to this project.”

Food processing—in which cassava, a root vegetable, is made into gari, a type of flour—is a common form of employment for rural women in Ghana. What QueenTech does is provide low-cost electric graters and mechanical presses, machines that allow women to process cassava seven times faster than traditional means.

For women looking to start or grow a food-processing business, these graters and presses are a powerful boost. According to a QueenTech study, women can reduce their cassava-processing costs by 50% with the aid of the nonprofit’s machines. QueenTech also offers zero-interest microloans to help women buy the graters and presses.

Making a Goal

Under the supervision of Benjamin Linder, an Olin professor of design and mechanical engineering and the director of the Affordable Design and Entrepreneurship program, the eight students in the course were ready for a meaningful semester, one that promised to have real-world implications. But, surely as it disrupted everything else, the pandemic affected their work, and they quickly had to adjust. “It was definitely a tough transition,” says Alayoub. “It was tough on all of us.”

“There is a big gap in the resources available to women compared to men. The opportunity to close that gap drew me to this project.”

Khalid Alayoub ’21

Some students in the course originally were focused on testing and improving the machines’ design using Olin’s machine shop, but now unable to access campus, those students are taking on other work, such as planning on how to get parts manufactured.

Meanwhile, Alayoub and his fellow Beaver, Jack Flynn ’20, were tasked with handling social media, performing a financial analysis, and most significantly, fundraising. The initial plan was to fundraise by going door to door, primarily in Wellesley, but now they’re hoping to seek donations online. The goal is to raise $8,000, which is required to sustain QueenTech’s operations.

As he strives to raise those needed funds, Alayoub thinks of the women so far away in Ghana who will be helped by QueenTech’s machines. “The pandemic has given us many challenges, but we are determined to meet our goal,” he says.

Posted in Community